Medical technology

Bonding, Potting, Sealing: With maximum reliability and process security

Medical technology places the highest demands on reliability and process safety in the production process. Particular attention is paid to the assembly of medical products – not only because of the high regulatory requirements. It is not uncommon for bonding, encapsulation or sealing to take place under cleanroom conditions.

Our dosing systems and dosing components enable you to manufacture medical devices and parts with process reliability. Even with the most demanding requirements. After all, your customers’ lives depend on it!

Our purely volumetric dispensers allow continuous and pulsation-free dosing. And this is regardless of the viscosity of the adhesives, sealants, or potting compounds to be processed. The technology is particularly gentle and low-shear. This video clearly demonstrates the advantages of our pharmaceutical dispenser series.

Application examples from medical technology

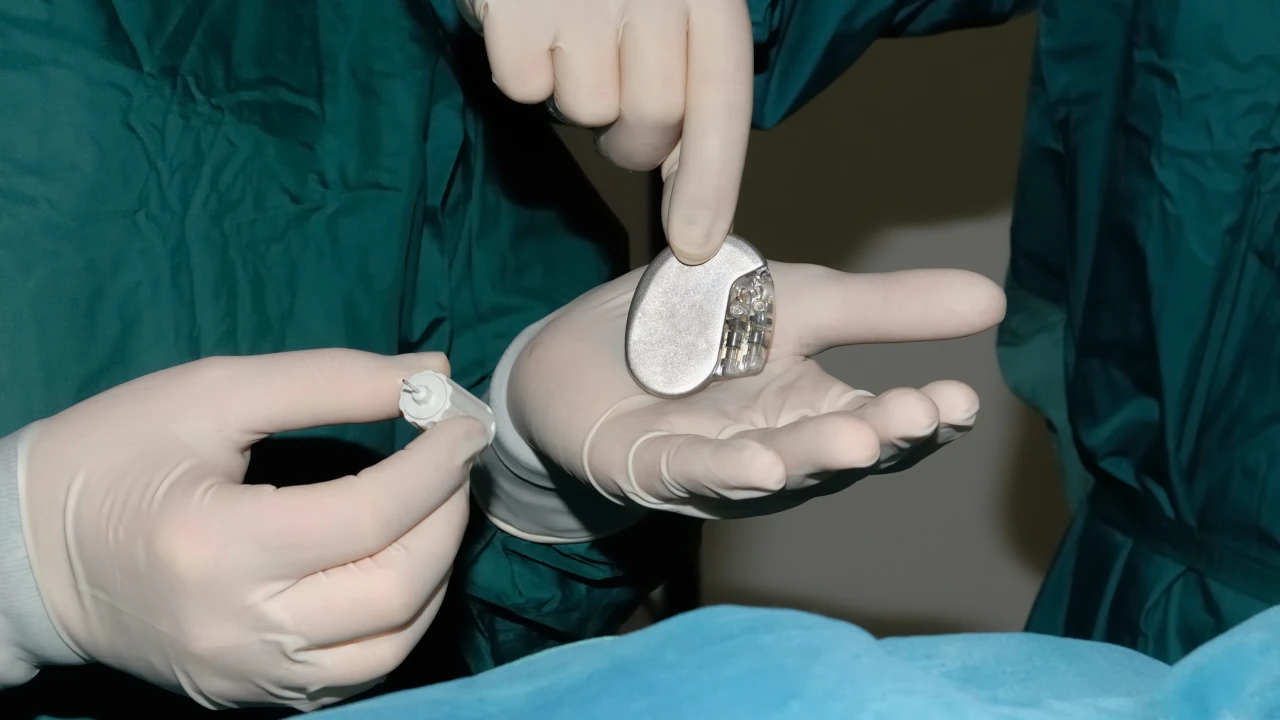

Bonding Pacemaker Shells

One application for our dosing pumps is bonding of pacemaker shells. Both with one-component and two-component adhesives.

We guarantee absolutely precise work in all applications: Because even with very fine dosing dots or lines with extremely small volumes of material, we achieve an exact mixing ratio. From the beginning to the end of the dosing bead.

You benefit from an adhesive bond in many ways:

- Low or non-existent thermal load on the joining materials.

- Surface and microstructure of the components to be joined remain unchanged during bonding.

- An adhesive bond can also have sealing properties.

- Nearly all components can be bonded – from very small to very large.

- An adhesive joint with UV adhesives allows repositioning of components during assembly.

At best, medical devices are manufactured fully automatically. Since manual handling is the biggest cost driver. You can read here how the gaps in partially automated processes can be closed.

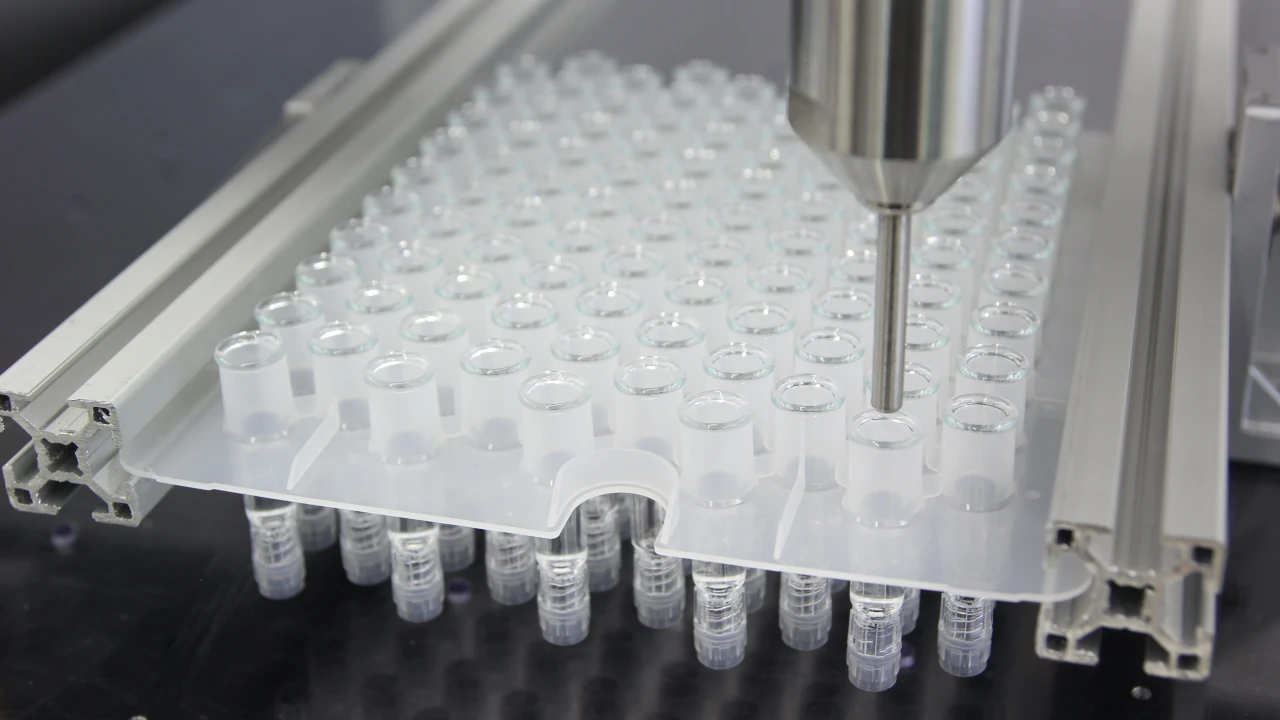

Bonding Catheter Components

Our dispensers are also used to bond catheter components. Depending on whether the catheters are made of glass, plastic or metal, RTV silicones or UV-curing adhesives are generally dispensed here. We guarantee very fast application with reproducible adhesive application – with a repeatability of >99 %.

A look at the developments in catheters shows the potential of, for example, adhesive bonding technology as a component of automated production in the field of catheter manufacturing. There is hardly a medical field in which catheters are not used. Whether in intensive care medicine for ventilation, in urology as a bladder catheter or in cardiology as a heart catheter – the list could go on.

In simple terms, the manufacturing of a catheter always begins with the extrusion of the tubes, which in the next step must be bonded to the so-called connectors. This adhesive connection must simultaneously ensure the tightness of the catheter. With our micro dispensing brand preeflow, even the smallest quantities of adhesive are applied with pinpoint accuracy. The volume is demonstrably the same throughout the entire production cycle. The delivery rate can be optionally changed if required by a specific component of the catheter, such as balloon, cuffs or even connectors. Even after the delivery rate has been adjusted, the dosage is exact.

An optimal process combines extrusion, cutting and bonding via an automated process. As the error potential is highest during manual joining. We will be happy to advise you on the implementation of such a process – simply fill out our contact form.

Process-reliable filling of high-viscosity products in medical technology

Our dosing technology enables the process-safe filling of viscous, shear-sensitive, or abrasive products and so-called semi-solids. It is perfectly suited, for example, for dermal fillers such as hyaluronic acid or liposome-based depot drugs.

Filling is flexible but highly precise. The net dosing time can be less than one second per syringe – with a filling accuracy of >99%. Our special design allows a programmable suck-back, which ensures a defined thread break and prevents unintentional dripping or thread pulling.

Read here which semi-automatic and fully automatic solutions are available. And which other advantages you can use for your production.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.