Emptying Systems

Making emptying child’s play

Whether it’s a cartridge, tin, bucket or barrel: Our emptying systems makes the emptying process easy. And with our accessories, barrel changes at viscosities of around 80,000 to 7,000,000 mPas are performed quickly, cleanly and in a way that is gentle on the product. Integrated into a dosing system, it is possible to not only empty containers but also to supply the application systems directly (filling fluids).

Before a product can be filled, mixed or dosed, it is often necessary to remove it from its original container. For ViscoTec, neither the size of the barrel nor its shape makes any difference here. We will make sure that you find just the right systems (barrel emptying system, barrel unloading, cans emptying, bucket emptying, cartridge emptying systems and many more) that are perfectly coordinated to your original pail and meet your exact requirements. For excellent emptying and supplying results.

Fluid emptying systems

Continuous and constant product emptying for seamless production without interruption.

- Container volume: 100 ml to 1,500 l

- Emptying capacity: individually customizable

- Viscosities: up to 7,000,000 mPas

We would be delighted to find out which model best suits your production process.

Emptying systems “Industrial”

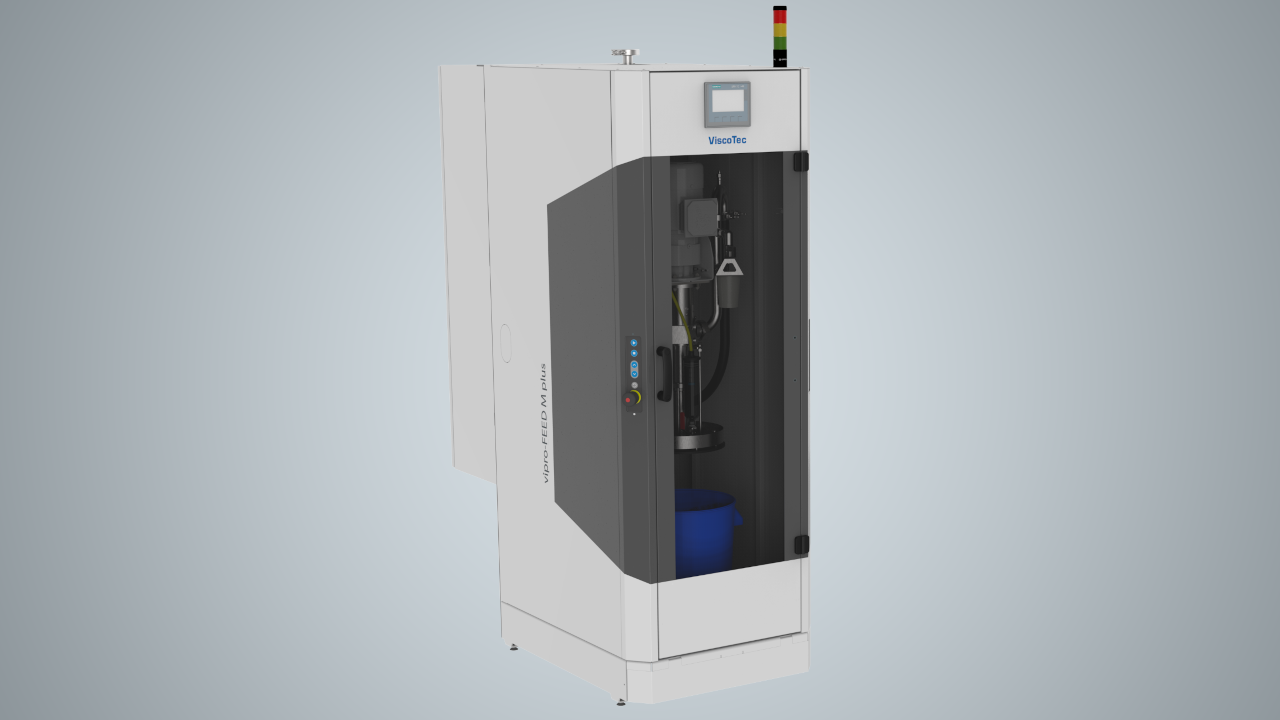

vipro-FEED M plus

- Automated and steady emptying of containers up to approx. 30 liters

- For medium to high viscosity materials

- Housing for machine safety and protection against dirt contamination

ViscoMT-XS

- Container sizes: from approx. 5 l to 50 l

- Viscosities: approx. 30,000 to 7,000,000 mPas

- Max. removal performance resp. speed: 810 ml/min* resp. 80 rpm*

ViscoMT-XL

- Container sizes: from 50 l

- Viscosities: approx. 30,000 – 7,000,000 mPas

- Max. removal performance resp. speed: 9,8 l/min* resp. 80 rpm*

vipro-FEED DC

- Automated and steady emptying of double-chamber cartridges

- Suitable for double chamber cartridges sizes 200 and 400 ml, others on request

- Viscosities: at least up to 100,000 mPas

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationViscoMT-C

ViscoMT-CM

ViscoMT-D

- Container sizes: approx. 100 ml to 5 l

- Viscosities: approx. 30,000 to 1,000,000 mPas

- Max. removal performance resp. speed: 136 ml/min* resp. 80 rpm*

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationEmptying systems “Hygienic”

ViscoMT-XS

- Container sizes: from approx. 10 l to 50 l

- Viscosities: up to 7,000,000 mPas

- Flow rate: up to 2,5 l/min

ViscoMT-XM

- Container sizes: from approx. 50 l to 1,500 l

- Viscosities: up to 7,000,000 mPas

- Flow rate: up to 90 l/min (larger flow rates possible on request)

Our ViscoMT emptying systems are suitable for medium to high-viscosity liquids. The removal can be made from a wide variety of vessels: Cartridges, cans, pails, buckets, barrels, and others. Both conical and cylindrical barrels and plastic buckets can be emptied. Our emptying systems are not suitable for bulbous plastic barrels, for which conventional barrel pumps are better suited.

Functionality of the emptying systems with follower plate

At the heart of our systems lies a vertically arranged progressive cavity pump. And it conveys the material gently, pressure-stable, and very evenly from the respective vessel. It functions like an endless piston, by conveying the product from the suction to the discharge side. Further components are the follower plate with a flexible wiping lip and the operating unit. The dosing pump is mounted directly on the follower plate – both are lowered together, and the flexible wiper ring or wiper lip seals the vessels accordingly.

Depending on the version and size, the entire emptying system is housed in a base frame with a barrel loading ramp. Larger vessels such as 200 l barrels are simply pushed under the system directly onto the production floor or, together with a pallet, simply under the ViscoMT-XL.

To start the emptying process, the follower plate is moved into the vessel until it rests on the surface of the liquid. The lowering device pushes the pump with a follower plate onto the material. And generates a slightly increased pressure in the bucket. This facilitates emptying via the pump, which at the same time also has a certain suction effect. As emptying progresses, the follower plate moves down into the vessel – almost pressure-free and with gentle handling of the product, due to our technology.

During the process, the wiping lip seals off the inside wall of the vessel. And at the same time removes any possible product residue from the vessel wall. Even dents, bulges, and barrel creases are, to a certain extent, compensated for. At the end of the emptying process, the follower plate sits on the bottom of the vessel. In this way, we achieve a degree of emptying of over 99 %.

Sensors detect when the follower plate has reached the bottom. The emptying process is then interrupted. A ventilation valve on the follower plate is then opened and the pneumatic lifting device lifts the complete unit consisting of follower plate and progressive cavity pump out of the container. In the event of partial emptying or interruption of production, the entire system remains in the vessel and serves as a closure.

ViscoMT for two product ranges: Industrial and Hygienic Design

We offer the emptying systems in two product lines: Industrial and Hygienic Design. For the Industrial line, the vipro-FEED M plus, ViscoMT-D, -XS, and -XL versions are available. For the Hygienic line, the ViscoMT-XS, and ViscoMT-XM. Almost all versions are mobile, only the D and XL version of the Industrial range are suitable for stationary operation due to their weight or their portal frame.

The versions differ on the one hand in their maximum flow rate. For the industrial versions, it is between 136 ml/min and 4 l/min. No large flow rates are required for dosing adhesives and similar materials. In the Hygienic versions, the maximum flow rate is between 1 l/min and 30 l/min. This is because the Hygienic versions are usually used for rapid pumping and filling of significantly larger quantities.

The designs also differ in terms of the barrel and container volumes, diameters, and heights to be handled. If required, the designs can also be customized. For example emptying a tank truck or in connection with a roller conveyor – depending on the requirements of your application.

Special materials for the ViscoMT in Hygienic Design

All elastomer materials in the emptying systems of Hygienic Design are FDA-compliant and approved for contact with food, for example. Furthermore, we work with stainless steel 1.4404 and 1.4571. The inner and outer surfaces of the stainless steel parts are polished. Surfaces in contact with the product have a surface roughness < 0.8 μm. It goes without saying that the GMP guidelines were implemented in the design of the progressive cavity pumps. They are designed to be hygienic and easy to clean and are available in protection class IP54 as a standard. Higher protection classes up to IP67 are available upon request.

Application example Visco MT Hygienic emptying system in the food industry

In the cosmetics sector, the fillings can be mascara, Vaseline or other cream-like media – i.e. products with highly fluctuating viscosity. Fillings with fruit pieces can also be dosed gently, due to the very smooth operation of the progressive cavity pump.

The fillings are dosed from the tank vehicle to a buffer tank and from there to the production line. This processes around 30 l of these fillings per minute. And with the same dosing capacity, the barrel emptying system supplies the buffer tank. In the event of a product change, the product nozzle of the progressive cavity pump is connected to a CIP system and the pump is cleaned without dismantling it.

If no CIP system is available, the pump can be dismantled in just a few steps, without special tools, and then cleaned manually.

In the video you can see a highly viscous caramel sauce being emptied from a barrel:

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationApplication example Visco MT Industrial emptying system in the automotive industry

In an application example, a moisture-curing silicone is emptied from a 20 l bucket. The material is used for sealing and bonding an electronics housing. A secondary ViscoMT-XS is used to empty material from the pail and feed it to the dispensers. When one bucket is empty, the system automatically switches to the second system, for uninterrupted feeding without system downtime. There is sufficient time for the operator to change the empty pail.

Unlike hygienic applications, the production lines in industrial use generally always run with one and the same product. This also minimizes the risk of material contamination, which could lead to negative chemical interactions.

Several dispensers in different dosing stations are responsible for dosing silicone, which apply the material to the components. The emptying pump is set and controlled in such a way that a sufficiently high flow rate arrives at the actual dosing pumps. And at the same time a bare minimum inlet pressure is applied to the dosing pump. This enables the pump to dose the required quantities in a stable and reliable manner and at speeds with extremely high precision.