Dispensing Systems

Perfectly coordinated systems

We optimize your process with highest accuracy, absolute reliability and speed. Our core competence is complex tasks in the high-end automation of production and filling lines.

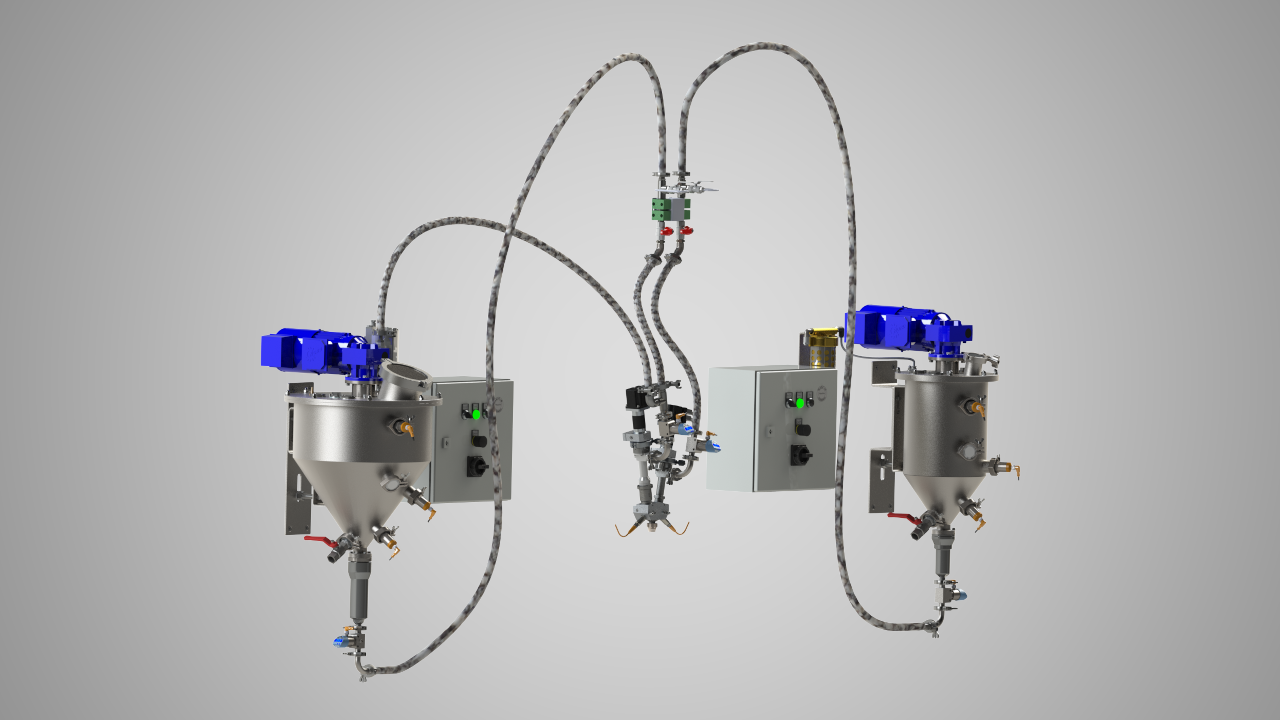

Dosing systems from one source

As a one-stop-shop, we enable a simple and fast implementation of entire dosing systems. With only one contact person you receive all components for your complete application from one source: From emptying to preparing and to dosing. This guarantees successful interaction of all components.

All fluids showing a viscosity of up to 7.000.000 mPas can be conveyed and dosed almost pulsation-free and with extremely low shear. We offer comprehensive consulting for every application and, if required, extensive tests will be carried out in close cooperation with you as our customer. The dosing pumps and systems are perfectly adapted to your respective application whether it is the food sector, the e-mobility industry, the aerospace field, the medical technology, the pharmaceutical industry and many other branches.

Quality Made in Germany

From precise micro dispensing, in the microliter range, to speed-proportional bead dosing, from potting applications, two-component mixing applications or from high precise filling under highest hygienic requirements for the pharma industry to liquid preparation and barrel emptying of semi-solid pastes: ViscoTec products cover a wide range of applications.

From the initial idea to the outgoing goods inspection: All process steps are worked out and implemented in Töging/Germany. Besides the quality feature, Made in Germany and the „Think global, act local“ approach, we not only ensure the quality of the dosing systems, but also optimum coordination and process reliability in all projects.

25 years of experience

To be well prepared for the future challenges of the numerous branches, we steadily improve our products, develop new ideas and put highest value on quality and service. Together with the creativity of our qualified employees, the many years of experience and the required competences in all application areas are reunited under one roof and form the basis of your trust in our products. We begin, where others give up! Let’s find your perfect solution, together.

Rotorspray – Material coating

vipro-SPIN

- Rotorspray for circumferential coating of material into boreholes and inner threads

- Contactless application, continuous spraying

- Suitable for lubricants, greases, anaerobic and other adhesives (low to highly viscous)

- Material feeding of the vipro-SPIN with various ViscoTec dispensers possible

- Four different spinning heads available

Just one click to the detailed report about the vipro-SPIN – including video.