E-Mobility

We master the challenges of the most difficult materials

In e-mobility dispensing applications, the focus is on fast and uncomplicated processing of the materials, combined with defined cost control. Applications of materials with the highest viscosities and abrasive properties are particularly challenging. Dispensing thermal paste, for example, is one of the challenges in industrial dispensing processes. It is imperative that the specific characteristics of the materials remain unaffected by the dispensing process. Even with a high filler content.

Our dispensing systems, based on the endless piston principle, offer excellent conditions for processing all low to high viscosity 1- and 2-component materials, such as gap fillers and liquid sealants or in potting and bonding applications.

In this interview, our specialists clarify many questions about dispensing applications in electromobility.

In the video, the application diversity of our dispensing technology in the production of electric vehicles becomes clear:

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

- Battery cell manufacturing, e.g. electrolyte filling

- Battery module and battery pack production, e.g. housing sealing

- Thermal management, e.g. thermal paste application

- Impregnation, e.g. trickling onto stator or rotor coils

- Fuel cell manufacturing, e.g. sealing on bipolar plate

- Bonding, e.g. bonding of battery carrier

- Potting, e.g. cell potting to fix the cell in place

- Sealing, e.g. inverter housing

Production of battery cells in E-Mobility

For safety and functional reasons, it is imperative to ensure degassed dispensing when filling batteries in e-mobility production.

ViscoTec dispensing systems guarantee that no air is introduced into the material during filling.

The repeatability of our systems is >99 %. Low material loss due to an optimized discharge system ensures optimized processes.

Furthermore, in battery production, highly accurate and reproducible application of the slurry is one of the key processes. ViscoTec offers many advantages here:

- Easy integration into already existing machines and systems

- Highly accurate application of the slurry

- Continuous dispensing process with endless piston technology

- Dispensing of low to high viscosity material (up to 7,000,000 mPas)

The metal-free dispenser can be used for filling the cells with a highly reactive electrolyte. This guarantees process reliability and an absolutely precise filling process. The metal-free dispenser is also used for other reactive materials, such as:

- Ionic Liquids

- Anaerobic adhesives

- Sulfur and chlorine based electrolytes

- Sulfuric Acid

- Bases

Here is a video about battery cells potting with Polytec material.

And here is a video about battery cells potting with Wevo material.

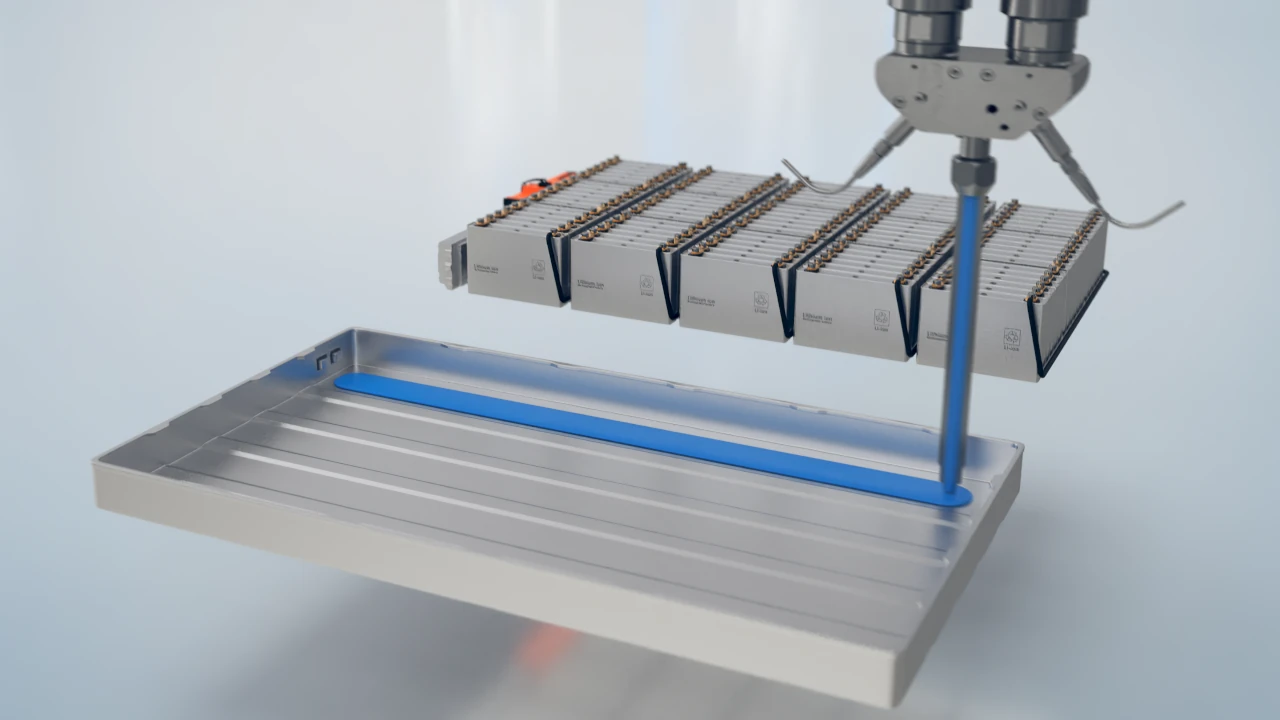

Battery module & battery pack production in e-mobility

As a safe, cost-effective and flexibly applicable sealing technology, ViscoTec’s volumetric dispensing technology has already proven itself over the last few decades.

Adhesive and sealing applications are also state of the art in the housing seals of battery management systems and battery packs in e-mobility. ViscoTec products are used in 1- and 2-component applications. The outstanding controllability is flexible and simple to use. In addition, heat input into the battery cells is prevented by avoiding or reducing welding processes.

Reliable heat management is one of the factors required for battery systems to operate at a high level of efficiency over the long term. This is accompanied by the generated heat dissipation from the electronic components as well as from individual cells and the complete battery packs or battery modules. ViscoTec dispensing systems are perfectly suited to apply high-precision 1- and 2-component thermal pastes as well as to dispense filled and abrasive materials. This results in long service lives with hardly any wear.

Potting or adhesive applications ensure the assembly of the individual battery cells in the assembly aids or on contacting elements. This applies to both 1- and 2-component. For safe material handling during the process, without dripping material.

Battery management systems in e-mobility are encapsulated to increase service life. This serves to protect them from external influences (such as moisture, dirt, vibration, etc.). And to improve their own properties (such as heat dissipation). We handle 1- and 2-component materials. Important: No air is introduced into the material during dispensing.

Here is an application video on YouTube.

Heat management / Application of thermal paste

Our dispensing pumps carry out the application and injection or filling by injection of TIMS or gap fillers onto and into battery modules or electronic components with absolute process reliability and repeatability. With both 1- and 2-component materials.

The result is continuous, repeatable dispensing that is gentle on the material – regardless of its viscosity. Our ceramic rotor ensures long service lives even when using highly abrasive materials.

For more information on this application, see our whitepaper.

Here you can see the corresponding video on YouTube.

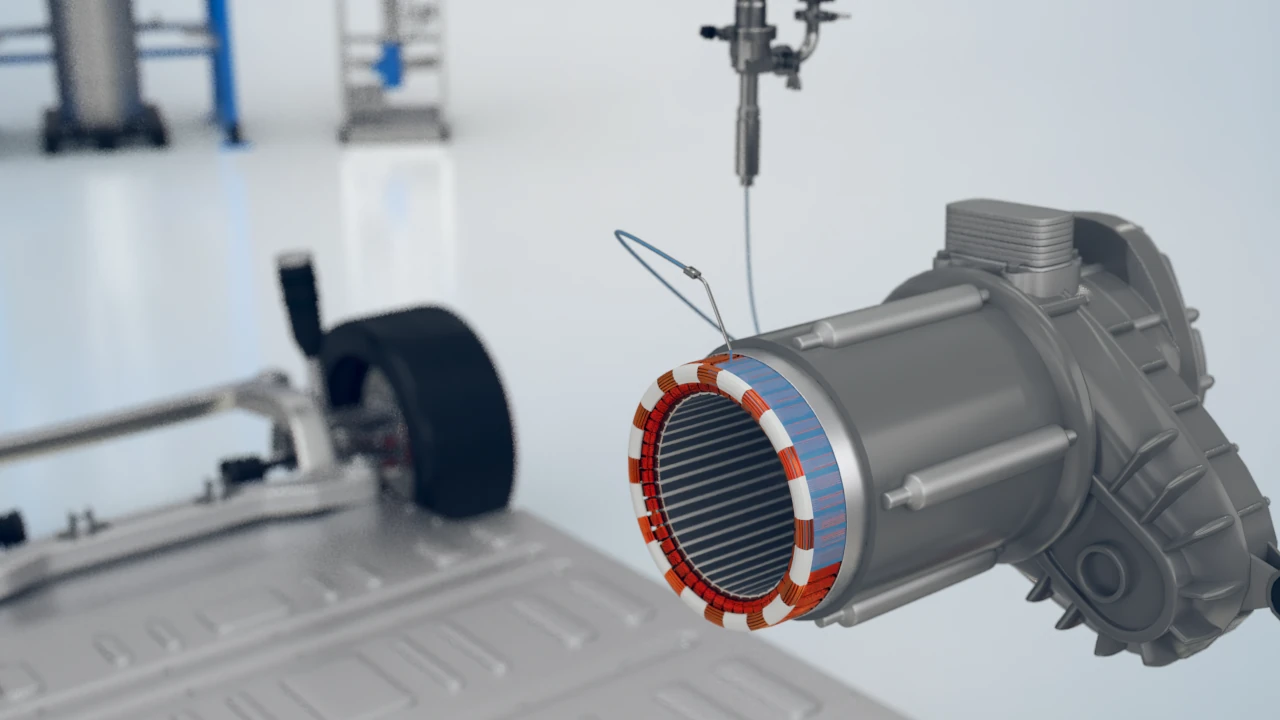

Impregnation of stator and rotor coils / Trickle impregnation

To protect and to increase the performance of the coils, they are impregnated with a resin during production of the electric motor (stator and rotor). The resin is applied to the coils via one or more nozzles.

The trickling process offers the decisive advantage of applying the exact amount of resin required at precisely defined points. The result is a high impregnation quality – coupled with a clean and material-saving process.

Your advantages:

- Perfectly prepared drip resin: Degassed, homogeneous, temperature-controlled.

- Safe material handling during the process, no unintentional dripping

- Easy programming of the dispensers, thanks to proportionality between speed and material output

- You can find more information about this application in our whitepaper.

Here you can see the video about our trickling system on youTube.

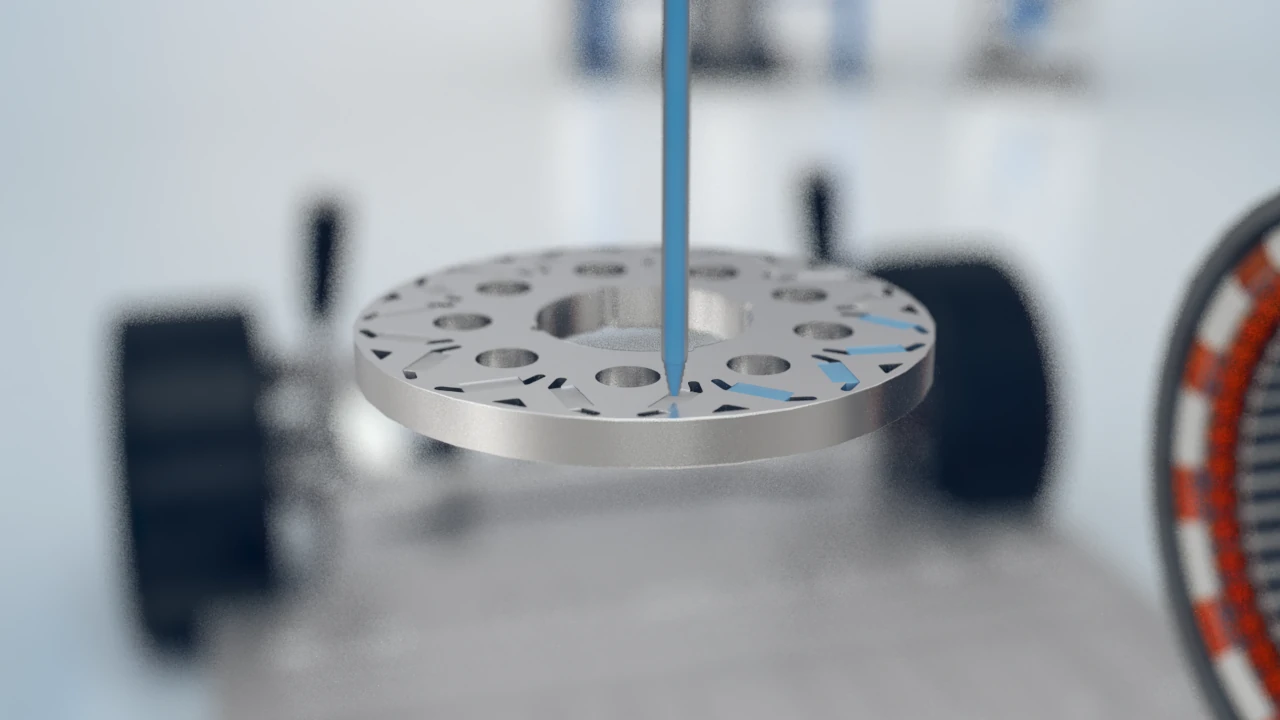

Fuel Cells Manufacturing

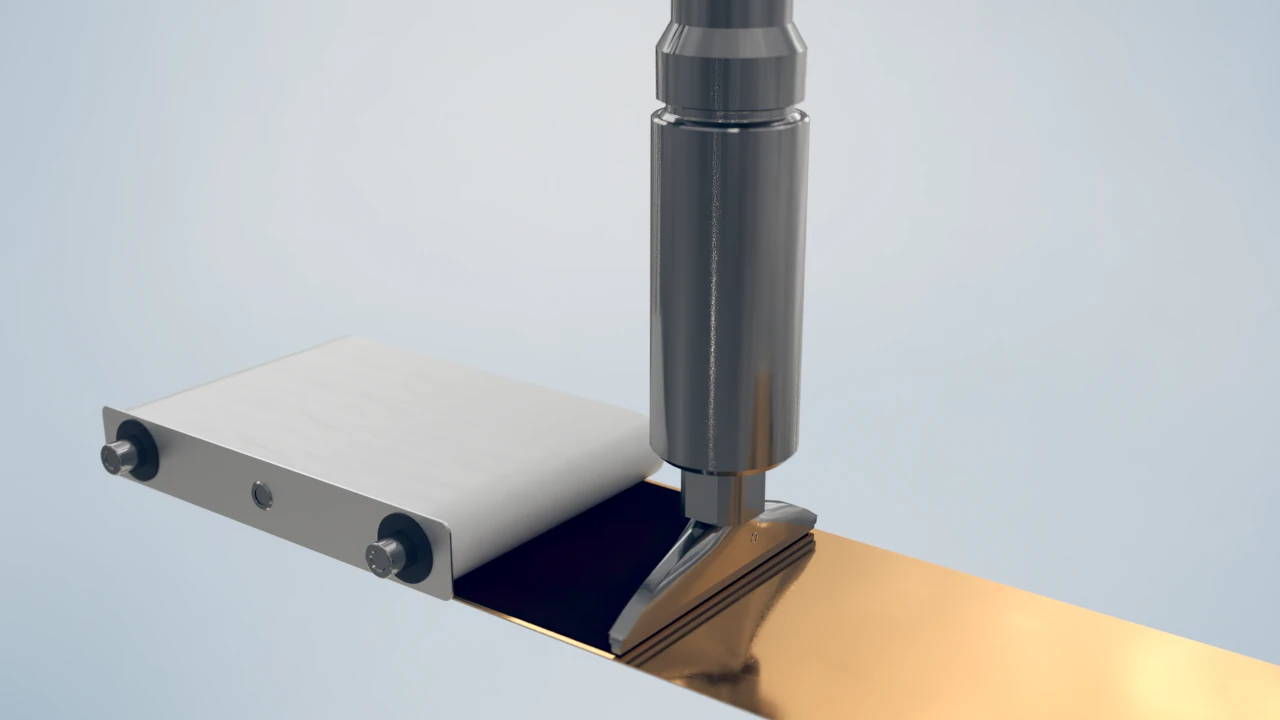

We deal with different dispensing applications in fuel cell manufacturing, such as sealing of bipolar plates. Our dispensers create reliable connections for extra durable cells.

Examples of use are:

- Dispensing of an adhesive and sealing bead on bipolar plates

- Continuous application to a membrane

For more information on dispensing technology in fuel cell manufacturing, see our white paper.

Bonding

- Dispensing without influencing the fillers (such as hollow glass beads)

- Cost and quality control through reproducible dispensing

- Dispensing in horizontal and vertical positions

Here you can see the video on YouTube.

Potting

To improve service life, electronic components such as electronic housings, connector housings and FFCs (flat-flex cables) are encapsulated. This serves to protect them from external influences (such as moisture, dirt, vibration, etc.).

And to improve their own properties (such as heat dissipation). We apply 1- and 2-component materials. Important: No air is introduced into the material during dispensing.

Here you can read the application report “Connector potting” with preeflow micro dispensers.

Sealing

Volumetric dispensing technology has already proven itself over the past decades as a safe, stable, cost-effective and flexible sealing technique.

Adhesive and sealant applications are also state of the art in housing seals, battery packs, or battery modules or inverters for e-mobility.

- Controllability is flexible and simple to use

- Consistently uniform sealing bead even with complex geometries

- No heat input into battery cells due to avoidance of welding processes

Here is the application video on YouTube.